More Details

1. Source and application of palm meal

Feed raw material catalog

Palm meal is a byproduct of palm kernel oil extraction, mainly produced in Southeast Asia, especially Malaysia and Indonesia. Palm meal, also known as palm kernel meal, English name PKE (Palm Kernel Expeller) or PKC (Palm Kernel Cake), is a byproduct of palm kernel oil products obtained by physical pressing or chemical extraction. Indonesian palm kernel meal is mainly obtained by physical pressing, where the yield of palm kernel oil (PKOER) is 43-45%, and the yield of palm kernel meal (PKER) is 53%-55%. The pure physical pressing process of palm kernel is simple, generally using two pressing processes. The palm kernel meal obtained by the first pressing has an oil content of about 13%. The first palm kernel meal is then pressed twice to obtain the final palm kernel meal product, which has an oil content of 7-8%.

As a feed raw material with good nutritional value, palm meal can provide protein and other nutrients in animal feed. However, due to the anti-nutritional factors it contains, such as non-starch polysaccharides (mainly β-mannan), its use in feed may be limited.

The nutritional value and digestibility of palm meal can be improved by microbial fermentation and the addition of enzyme preparations. When designing feed formulas, feed formulators should consider the nutritional components and anti-nutritional factor content of palm meal, use it reasonably, and improve its utilization efficiency in animal feed through appropriate processing. Through scientific feed formula design and proper processing and storage management, the role of palm meal in animal feed can be fully utilized to improve breeding efficiency.

2. Palm meal processing technology

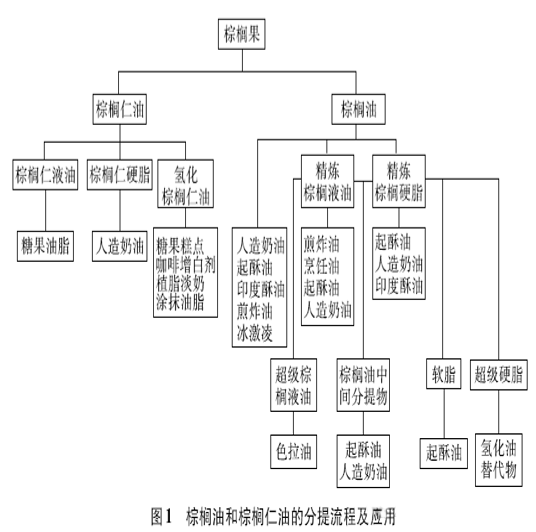

The above figure shows the rough processing process of palm oil, and the subsequent palm oil refining process will not be described. Palm oil extraction technology is relatively diverse, for example:

Screw pressing: After the oil palm fruit bunch is sterilized and threshed, the whole fruit (including the kernel) is pressed. Its advantages and disadvantages are that it can be processed in large quantities continuously, but the kernel is easy to break, the residual oil rate is high, and the functional components are seriously lost.

Hydraulic pressing: After the oil palm fruit bunch is sterilized and threshed, the kernel is peeled off and the flesh is taken out for pressing. Its advantages and disadvantages are high oil yield (70%-90%), but it can only be processed in batches and cannot achieve continuous production. It is suitable for medium-sized processing plants.

Water enzyme method: After the sterilized pulp is crushed, it is mixed with hot water/steam/enzyme solution for extraction and centrifugation. Its advantages and disadvantages are clean and efficient, with an oil yield of more than 90%, and can effectively retain functional components, but the operation is cumbersome and has not yet been promoted on a large scale.

Organic solvent method: Extract from palm oil processing waste liquid with food-grade solvents such as petroleum ether and n-hexane. The advantages and disadvantages are that organic solvents are introduced, and recovery equipment needs to be added, which has the risk of pollution. Most of them are used to recover oil from waste liquid.

Supercritical extraction: The oil palm kernel or the pulp fiber after oil extraction is extracted under a certain pressure and temperature. The advantages and disadvantages are high oil quality and long shelf life, but the equipment investment and operating costs are high, and it is mostly used for oil recovery or high-quality palm oil preparation.

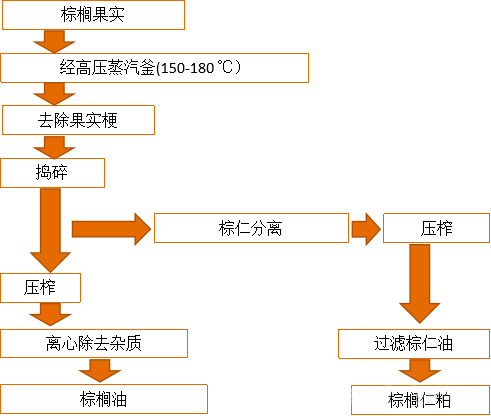

Through the process of boiling, crushing and squeezing, crude palm oil (CPO) and palm meal (PE) can be obtained from palm pulp; at the same time, during the crushing process, the palm fruit (i.e. palm kernel) is separated, and then crushed and shelled, and the remaining kernel is squeezed to obtain crude palm kernel oil (CPKO) and palm kernel meal (PKE).

After crude palm oil is refined and free fatty acids, natural pigments and odors are removed, refined palm oil (RBD PO) and palm salad oil (RBD PKO) are obtained.

According to different needs, crude palm oil can be fractionated to obtain palm oil with different melting points such as 24 degrees, 33 degrees, and 44 degrees.

In addition, according to the needs of different users, palm oil can be further fractionated and processed to form palm oleic acid (PFAD), palm olein (OLEAN), and palm stearin (STEARINE or ST).

Palm oil is rich in carotene (0.05%-0.2%) and is dark orange-red. This pigment cannot be effectively removed by alkali refining, and the oil color can be decolorized to a general light yellow by oxidation. Palm oil will gradually decolorize under the action of sunlight and air. Palm oil has a slightly sweet taste and a pleasant violet aroma. It is semi-solid at room temperature, and its consistency and melting point depend largely on the content of free fatty acids. In the international market, palm oil with a low free fatty acid content is called "soft oil", and palm oil with a high free fatty acid content is called "hard oil".

Brief description of palm kernel meal process

3. Quality Control of Palm Meal

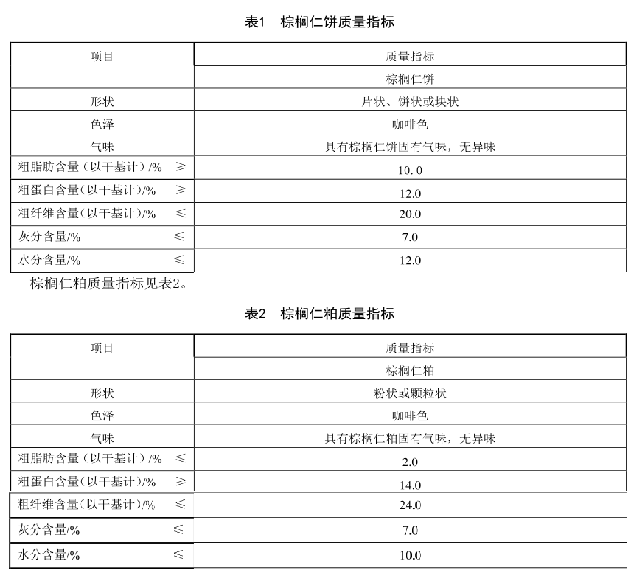

T∕CCOA 24-2020 Group Standard for Palm Kernel Cake

1. Sensory Identification

a. Color: coffee or brown or dark amber, fresh and consistent color.

b. Taste: fresh, with the inherent smell of palm kernel meal (coffee and wine), no peculiar smell, no peculiar smell such as mildew, fermentation, burnt and rancid.

c. Properties: powdery or granular coarse powder, good fluidity, no agglomeration. The temperature during processing has a great influence on the quality of the product, and overheated products should be avoided.

d. Impurities: The material after the oil palm kernel is shelled and pre-pressed or directly extracted by leaching (actually there will be a small amount of kernel shell), and any other substances other than palm kernel cake should not be mixed.

2. Physical and chemical testing

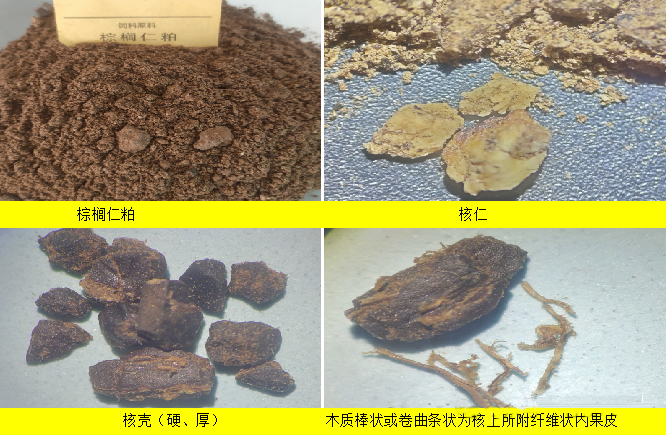

a. Microscopic examination: Characteristics of normal palm kernel meal

The main compounds in palm kernel meal are carbohydrates and lignin, among which the lignin content is as high as 13.6% (mainly due to the introduction of palm shell during crushing), which leads to its poor palatability.

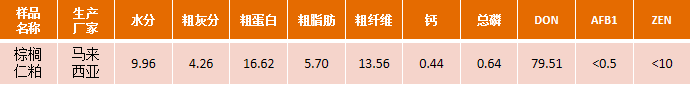

b. Conventional indicators: The quality requirements for palm kernel cake are set in 8 items, including: shape, smell, color, moisture, crude protein, crude fat, crude fiber and ash.

Crude protein: Some suppliers/feed mills will agree to oil protein (crude protein + crude fat).